Jerseys Making Machine

Cixing Group, the world's largest manufacturer of Jerseys Making Machine.At present, the market has occupied the first place in the world for many years.Every year we sell tens of thousands of computer flat machines to countries all over the world.Based on independent innovation and caring servi......

Send Inquiry

Product Description

Cixing Group, the world's largest manufacturer of Jerseys Making Machine.At present, the market has occupied the first place in the world for many years.Every year we sell tens of thousands of computer flat machines to countries all over the world.Based on independent innovation and caring service, guided by the continuous development and change of market demand, Cixing made a wholly-owned acquisition on the top three global Jerseys Making Machine in 2010, Switzerland Steiger, forming the innovation mechanism of“Independent research and development oriented, cooperative research and development, supplemented by global technology integration", based on strong R &D strength and continuous technological innovation, as of now, Cixing shares have gained more than 1000 national patents, 108national invention patents,7 international monopoly, and 10 software copyright.

Cixing is the largest Jerseys Making Machine factory in the world,It has various functions, no waste yarn bottoming, no scissors clamp mode, which not only saves knitting time but also reduces the cost of non waste yarn.Forced knocking over,bilaterial stitch,fast speed and other functions to lead the development of industry.

NEW HP2-52C-U

This model of Jerseys Making Machine is equipped with single carriage, dual system roller models can be selected from the comb, using Hengqiang integrated system.

The display displays varios knitting information and parameters, and visualizations in actual knitting process.Display knitting process: you can view the carriage mechanical's working status and actual position and the quantity already woven. In addition, the working parameters such as stitch, speed, tension and so on can be adjusted at any time when the machine is running, which facilitates the operation and saves time to maximum extent.

A good machine must have distinguished technology, so does Cixing. Its looping formation quality, even for the very friable yarns, will be also capable to meet the requirements of fabric on bulk density or compactness. The free needle pitch allows you to choose different ones on the same machines according to the change of seasons.

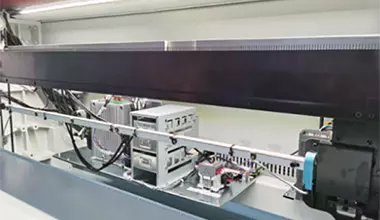

Full motor 5.2-inch ultra-small carriage, motorized transfer cam, rapid return, carriage does not wait when transfer needles, double racking, effectively reducing carriage route and course, greatly improving machine stability and efficiency.

Dynamic stitch function, which can realize multi segment stitch knitting in the same course(one course can support 256 changing areas), without break up the course, increase pattern design diversification, can realize different knitting stitch with different knitting area in the same course; The stitch fine adjustment function on both sides can effectively solve the problem of different length of fabric and increase the flatness of fabric. New forced dewinding function, can be segmented control, can solve the problem of missing needles in the knitting process.

Full Cam Motorized CarriageWith the full cam motorized super small carriage, the cam knit, tuck, transfer actions are controlled by motors, greatly reducing the cam failure rate. The carriage systems are cooperated with optimized course to have shorter return distance, faster return speed, truly achieving high-speed, efficient and stable production.

Display ScreenIt adopts industry LCD displayer with graphic touch control, multi color, time monitoring function. The data of knitting amount, time, speed, roller, density, yarn carrier, etc. is clearly shown and can be adiusted in the proless.

Stitch MotorWith dynamic stitch function, using high speed stepping motor, milti stitch function can be achieved in one line.

Servo MotorUsing CANI communication control, can achieve the rapid return and direction changing of the machine carriage, accurate positioning, smooth commutation.

Motorized Inversion BarDriven by motor connecting rod, reversing more accurately.

Yarn StorageYarn Storage could reduce resistance while the yarn is moving, is suitable for fabric with lack of elasticity and brittle fabric such as cashmere yarn, rabbit hair yarn.

Intelligent CombNo waste yarn to knit the fabric bottom, save the machine knitting waste yarn time, reduces the workload of employees. It greatly reduces the enterprise cost. The main yam lead is equipped with a yarn pressing device, so the main yarn lead wire is short, which saves the main yarn and reduces the phenomenon of poor doth dropping and fabric winding caused by the long lead head. Servo closed-loop control is used to accurately control the pulling of the comb, it solve the two different density problems which caused by rib fabric pulling by comb and pulling by roller. The pulling force is more uniform, the fabric effect is better, and the fabric bottom is more beautiful. 5-12G optional.